Image 1 of 3

Image 1 of 3

Image 2 of 3

Image 2 of 3

Image 3 of 3

Image 3 of 3

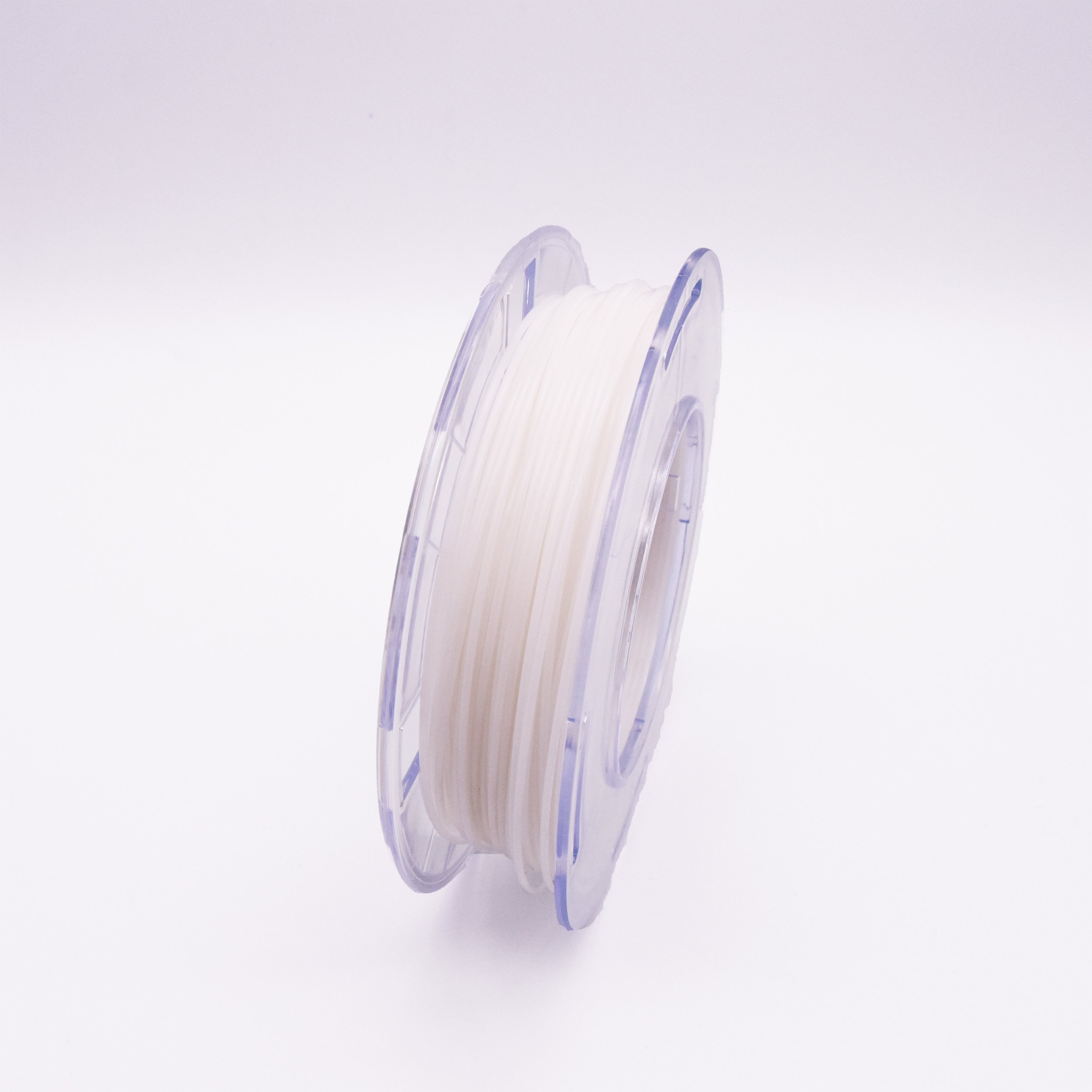

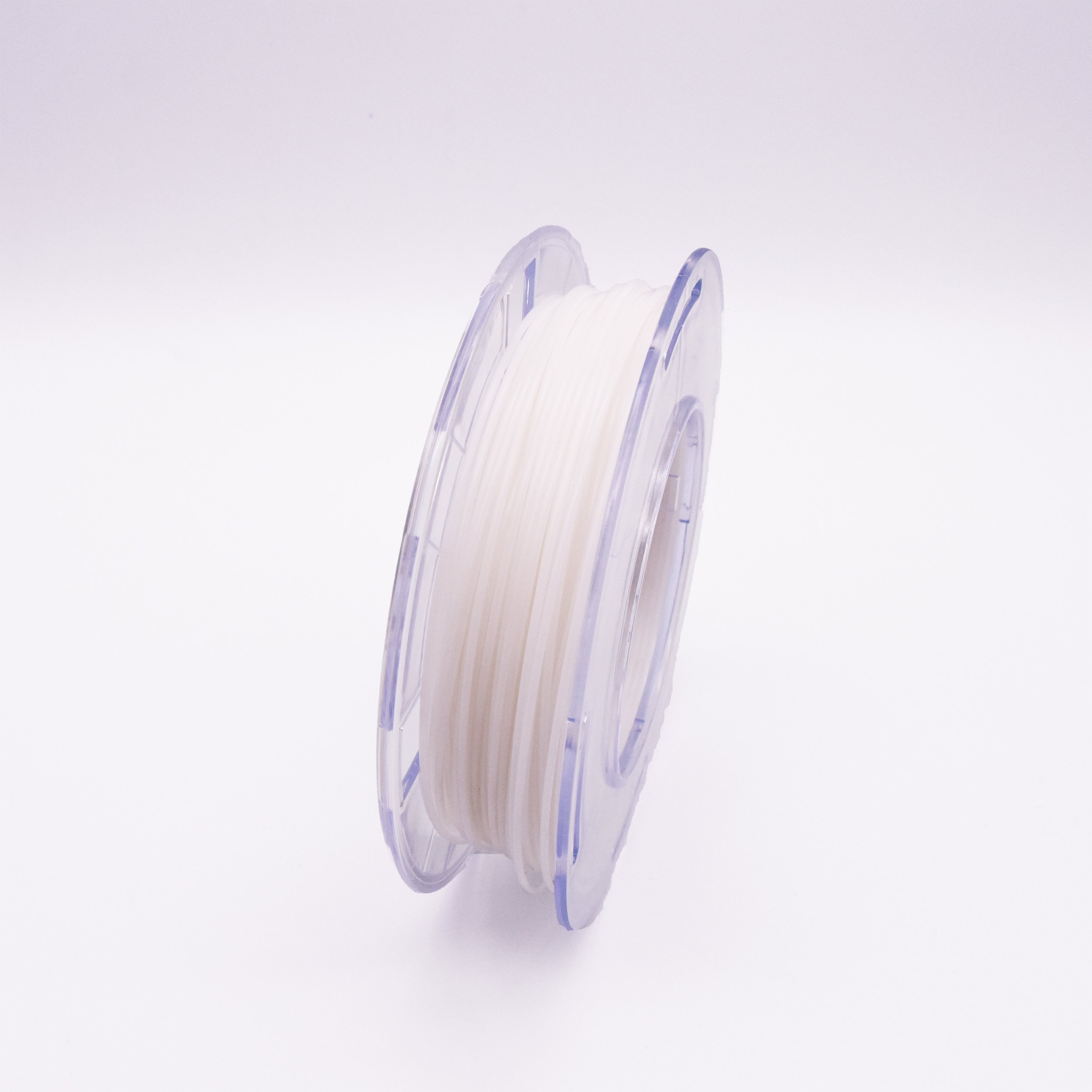

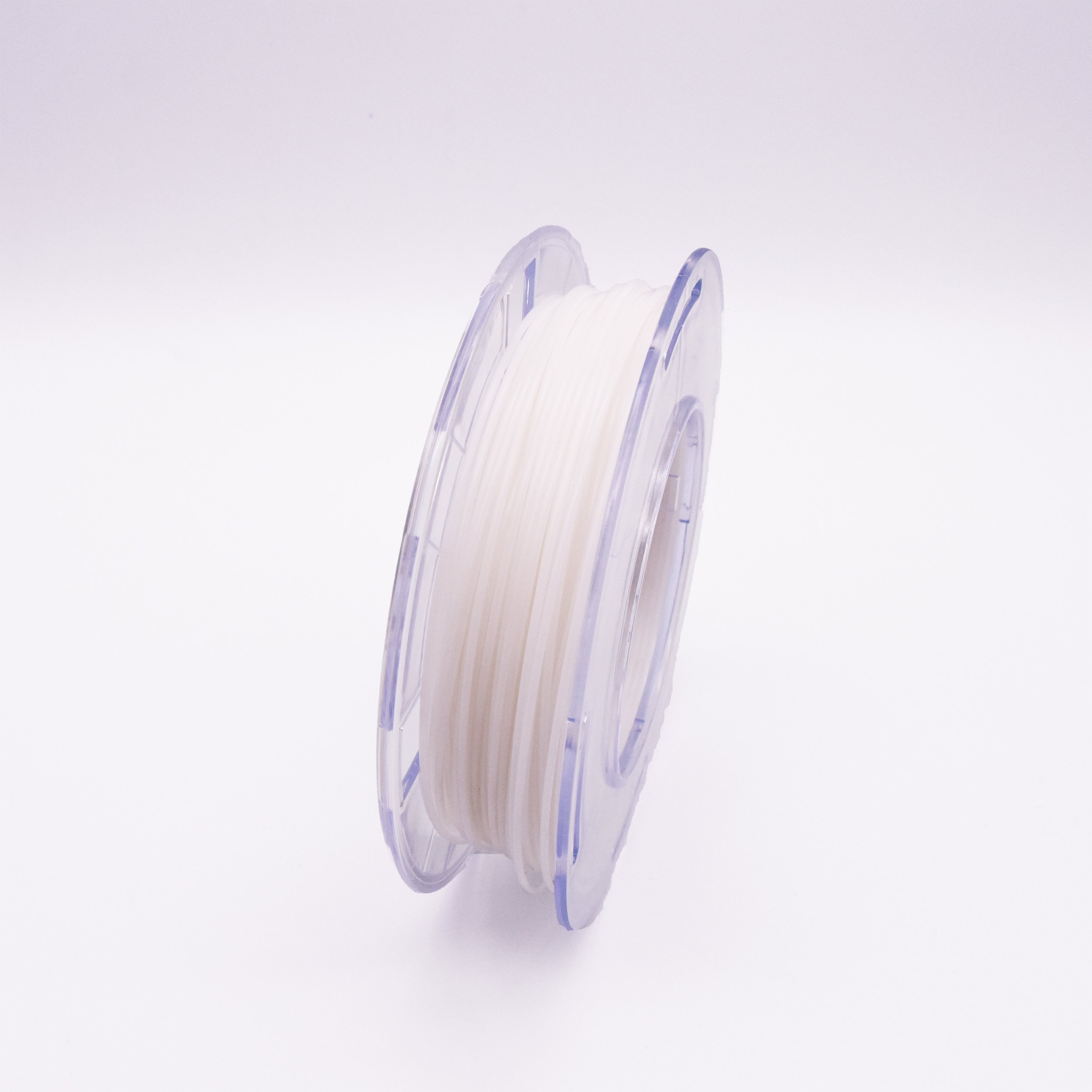

Novus Bonlecule Medical Grade Bioactive 3D Printing Filament

Bonlecule is an implantable bioactive material, a PMMA-based biomaterial with evenly distributed nano-hydroxyapatite (approximately 20nm in length). Unlike other hydroxyapatite-filled materials reported in literature or by other manufacturers, Bonlecule is highly resistant to breakage even with a 0.4mm printer nozzle. This durability is achieved through our patented nano-hydroxyapatite-copolymer synthesis process.

Bonlecule is an implantable bioactive material, a PMMA-based biomaterial with evenly distributed nano-hydroxyapatite (approximately 20nm in length). Unlike other hydroxyapatite-filled materials reported in literature or by other manufacturers, Bonlecule is highly resistant to breakage even with a 0.4mm printer nozzle. This durability is achieved through our patented nano-hydroxyapatite-copolymer synthesis process.

Bonlecule is an implantable bioactive material, a PMMA-based biomaterial with evenly distributed nano-hydroxyapatite (approximately 20nm in length). Unlike other hydroxyapatite-filled materials reported in literature or by other manufacturers, Bonlecule is highly resistant to breakage even with a 0.4mm printer nozzle. This durability is achieved through our patented nano-hydroxyapatite-copolymer synthesis process.

Features

Excellent Bone-Like Mechanical Properties and Osteoconductivity

Stable for Permanent Implantation

Biocompatible & Non-toxic (Certified to ISO 10993-5:2009, ISO 10993-10:2021, ISO 10993-11:2017, ISO 10993-23:2021, USP 88 Class VI and REACH)

Osteoblastic cell line MC3T3-E1 showed 2-fold increase in in-vitro cell proliferation studies

Radiopaque – Visible to X-Ray and MRI imaging

Sterilizable by Gamma Radiation, E-beam and Ethylene Oxide

Ready to use – Stored in vacuum sealed aluminum bag with desiccants

Ossfila Medical Grade Filament Packaging and Storage

Each new spool of Ossfila Medical Grade Filament is securely packaged in a vacuum-sealed bag with desiccant, ensuring optimal storage conditions. Under normal circumstances, drying is not required.

However, if the spool is exposed to air for more than 2 days, moisture absorption may occur, potentially impacting print quality. A common sign of excessive moisture is stringing during printing.

To prevent this, we recommend drying the spool in a 50°C oven for 24 hours prior to printing.