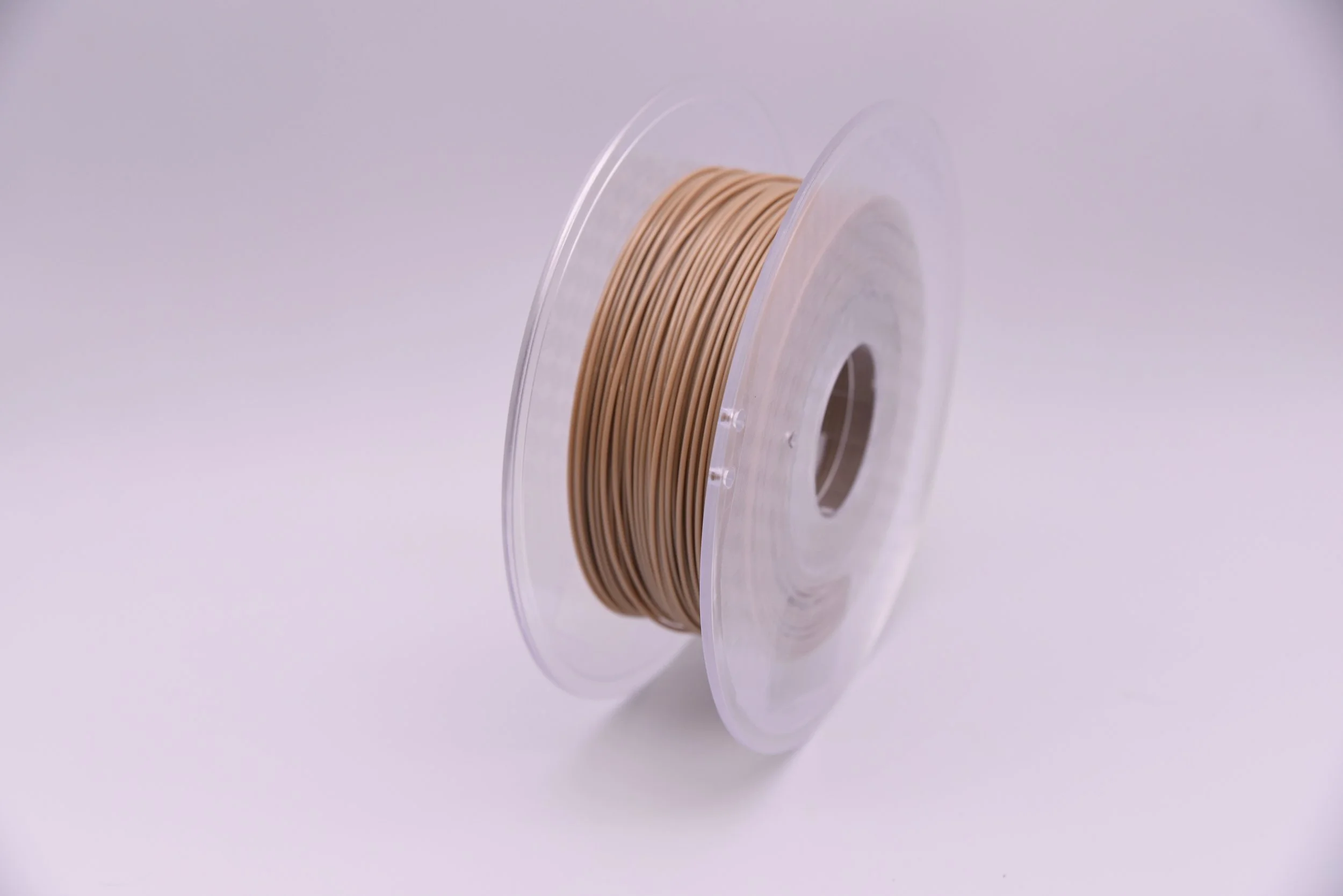

Image 1 of 4

Image 1 of 4

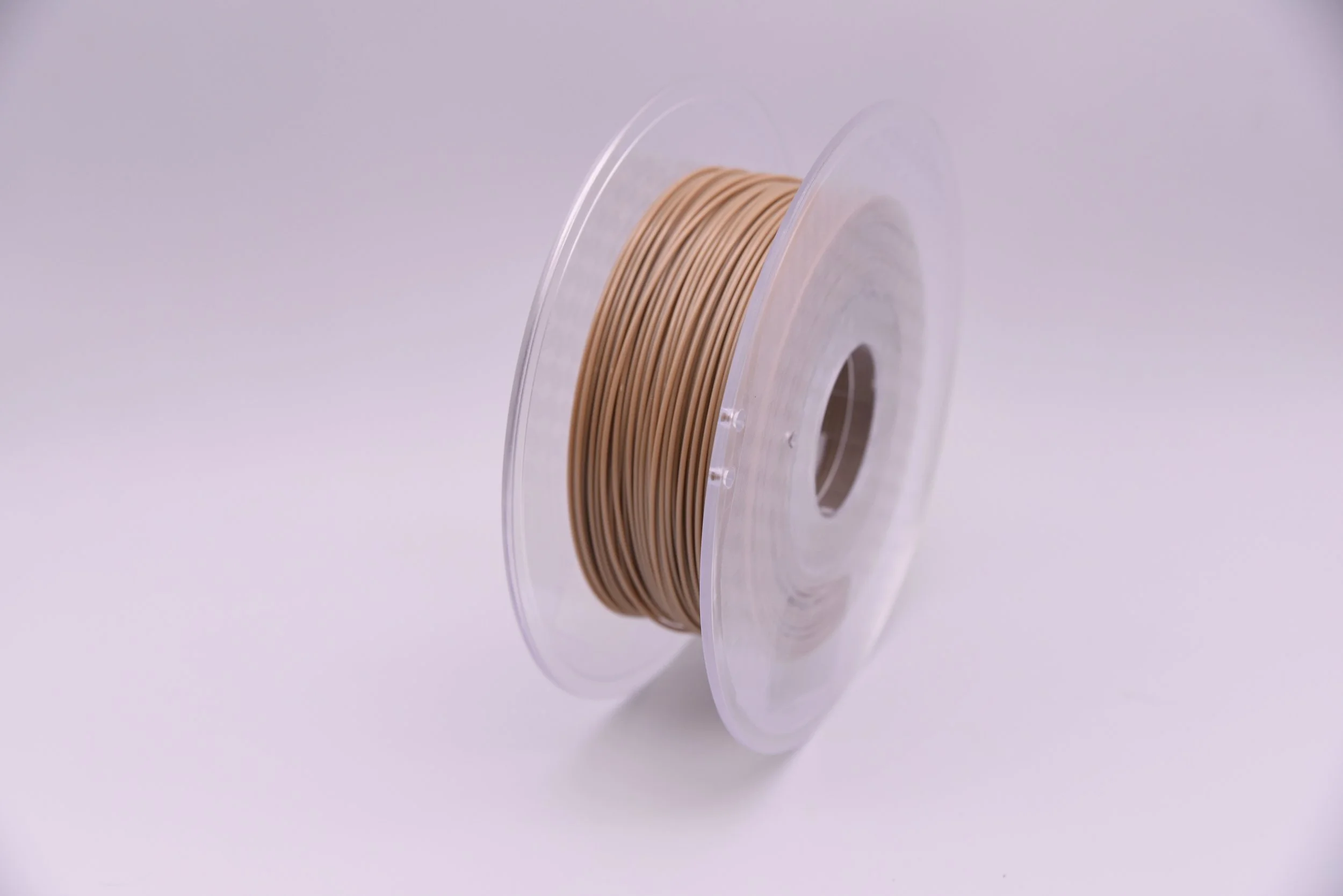

Image 2 of 4

Image 2 of 4

Image 3 of 4

Image 3 of 4

Image 4 of 4

Image 4 of 4

Novus Medical PEEK 3D Printing Filament

Manufactured in an ISO 13485-certified cleanroom, Ossfila Medical PEEK Filament is a high-performance, biocompatible, non-toxic, and chemically resistant 3D printing material, ideal for medical devices and permanent implants. Its medical-grade PEEK composition ensures the highest level of safety for implant production, making Ossfila Medical PEEK Filament one of the top choices on the market.

Manufactured in an ISO 13485-certified cleanroom, Ossfila Medical PEEK Filament is a high-performance, biocompatible, non-toxic, and chemically resistant 3D printing material, ideal for medical devices and permanent implants. Its medical-grade PEEK composition ensures the highest level of safety for implant production, making Ossfila Medical PEEK Filament one of the top choices on the market.

Manufactured in an ISO 13485-certified cleanroom, Ossfila Medical PEEK Filament is a high-performance, biocompatible, non-toxic, and chemically resistant 3D printing material, ideal for medical devices and permanent implants. Its medical-grade PEEK composition ensures the highest level of safety for implant production, making Ossfila Medical PEEK Filament one of the top choices on the market.

Features

High-performance thermoplastic designed for medical applications and permanent implantation

Exceptional mechanical properties with outstanding impact resistance, polishability, and UV tolerance

Chemical Resistance especially to acids

Biocompatible and Non-Toxic (USP 88 Class VI certified)

Sterilizable by Gamma Radiation, E-Beam and Ethylene Oxide (EtO)

Ready to use - Stored in vacuum sealed aluminum bag with desiccants

Compatible with all FFF/FDM 3D printers

Ossfila Medical Grade Filament Packaging and Storage

Each new spool of Ossfila Medical Grade Filament is securely packaged in a vacuum-sealed bag with desiccant, ensuring optimal storage conditions. Under normal circumstances, drying is not required.

However, if the spool is exposed to air for more than 2 days, moisture absorption may occur, potentially impacting print quality. A common sign of excessive moisture is stringing during printing.

To prevent this, we recommend drying the spool in a 50°C oven for 24 hours prior to printing.